Request A Quote

41 Spring Hill Rd, Saco,

ME 04072

ME 04072

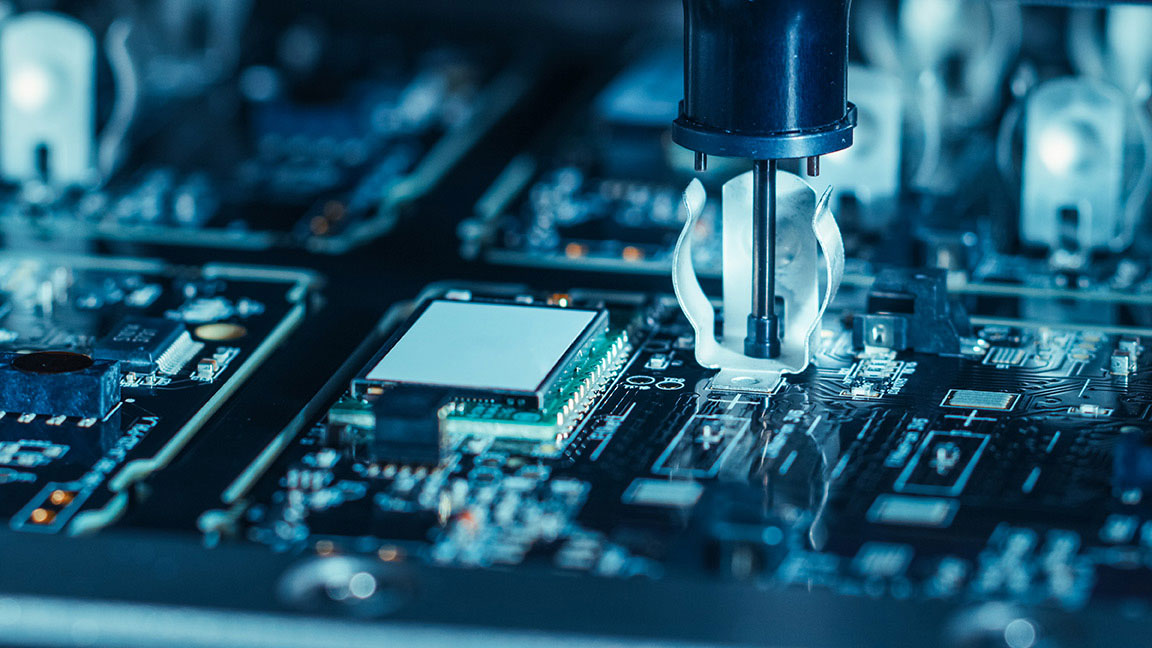

LAW Calibration crafts a precise calibration of electrical and electronics that is accurate and reliable and done in a manner that satisfies all industry standards. Our services include

We offer professional calibration services in the following regions